Typically, there is a huge variation in the emission current and lifetime of a field emitter array due to the exponential dependence of the emitter current on tip radii.

“Ordinarily at a given bias voltage, only a fraction of the emitters in an array would be working because the bias voltage is not large enough to make the duller tips emit, while the sharper tips burn out because of Joule heating,” Akintunde Akinwande of MIT’s Department of Electrical Engineering and Computer Science and Microsystems Technology Laboratories told nanotechweb.org. “However, if the current of each emitter is limited by electrical ballast, which in our case is a current source, burn-out of the sharper tips will be prevented and the duller tips will now have the opportunity to contribute to the total emission current.”

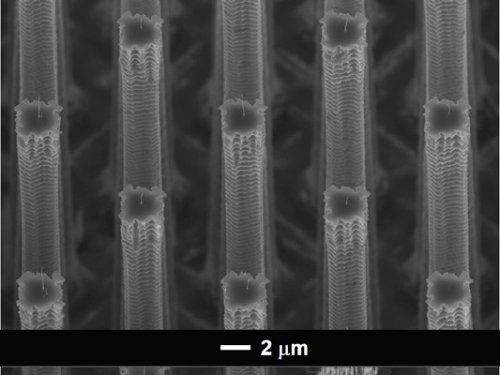

The group obtains current source-like behavior from its devices by taking advantage of the velocity saturation of electrons in silicon, which is encouraged through the use of high-aspect-ratio columns and doping.

As well as regulating current flow, the porous array could also play a role in controlling the distribution of liquids in micro and nanofluidic systems. One area under investigation by the team is electrospraying.

The performance of electrospray emitters improves if the units are scaled down. The size reduction decreases the start-up voltage and lessens any vaporization losses, but there are other factors to consider.

“Each electrospray emitter requires precise flow control because it can work steadily only over a certain range of flow rates,” explained Luis Velásquez-García of MIT’s Microsystems Technology Laboratories. “Our arrays of silicon columns can be used to custom design a porosity that is locally defined to match the flow rate of each electrospray emitter.”

By applying a thin-film coating to the reactive ion-etched array, the researchers can reduce the gaps between the vertical pillars from 9 µm to just 50 nm, which gives a variation of two orders of magnitude in porosity.

“The change in porosity implies a variation of five orders of magnitude in the fluid permeability,” added Velásquez-García. “This means that we have a very wide design space to match a flow rate for a given pressure drop and microfluidics layout.”

The researchers presented their work in Nanotechnology.

About the author

James Tyrrell is editor of nanotechweb.org.