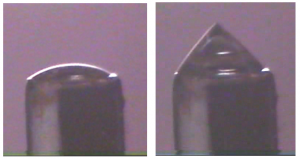

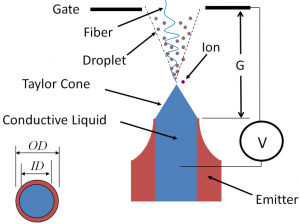

Electrospray refers to the technique to produce ionized species from electrically conductive liquids using high electrostatic fields. In electrospray ionization (ESI), the free surface of a conductive liquid snaps into a conic shape (Taylor cone) when the local electrostatic field is high enough (Fig. 1). The cone is the equilibrium surface between the surface tension effects and the electrostatic pulling, except at the apex of the cone where the electric fields are high enough to eject liquid.

We are interested in ESI because the phenomenon can produce micro and nano-scaled particles such as droplets, solvates ions, and fibers with small size variation. These particles can be used in a myriad of exciting applications with deep impact including mass spectrometry of biological macromolecules (the 2002 Nobel Prize in Chemistry was awarded to Dr. John Fenn because of this), fabrication of nanofiber-reinforced composites for high-performance structural applications, in-situ water quality monitoring for environmental applications, ultra-precise printing, etching, and coating, production of quantum dots and other nanoparticles, and nanosatellite propulsion.

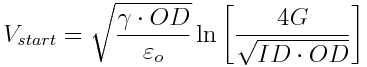

The start-up voltage of an electrospray emitter Vstart is

where γ is the surface tension of the liquid, G is the emitter-to-gate separation, εo is the electrical permittivity of free-space, and ID and OD are the inner and outer diameter of the emitter, respectively (Fig. 2). We are interested in scaling-down the electrospray emitters because, a as shown by Eq. 1, emitter scaling-down reduce the turn-on voltage, which results in less power consumption per emitter for a set current. We are interested in implementing massive arrays of electrospray emitters because the output of a single emitter (current, flowrate, etc.) is quite small, which severely limits the range of applications that can be satisfied with the technology. ESI multiplexing requires individual electrical/hydraulic flow control; otherwise, the emission uniformity is rather poor. In addition, flow regulation is required to set the electrospray emitter to work in steady-state, or to produce a particular kind of particle from a given liquid (for example, only ESI emitters with very low flowrate can produce only ions from highly conductive liquids; larger flowrates translate in ion/droplet mix). Finally, multiplexed electrospray requires proximal gates to achieve low-voltage actuation. We pioneered the field of MEMS multiplexed ESI sources and several of our contributions such as the decoupling of the emitter and electrode substrates to achieve high yield and good electrical insulation, and the individual ballasting of the emitters to achieve uniform and steady emission have been adopted by other leading research groups. We have worked on both internally-fed and externally-fed electrospray emitters, which work described in the next sub-sections.